Bando

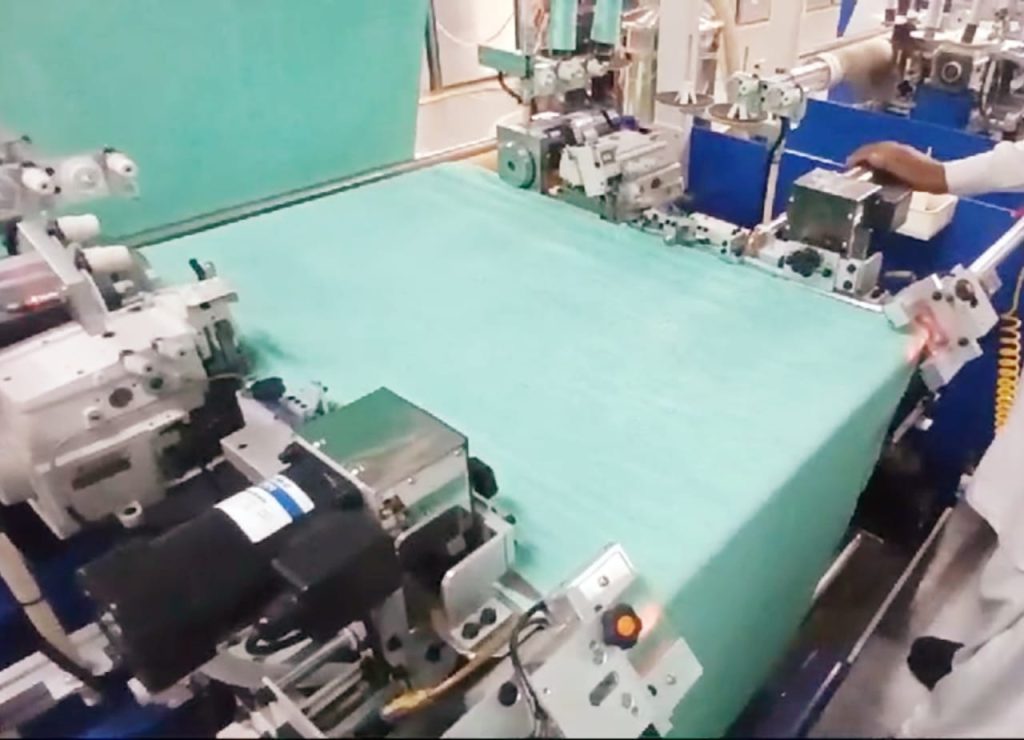

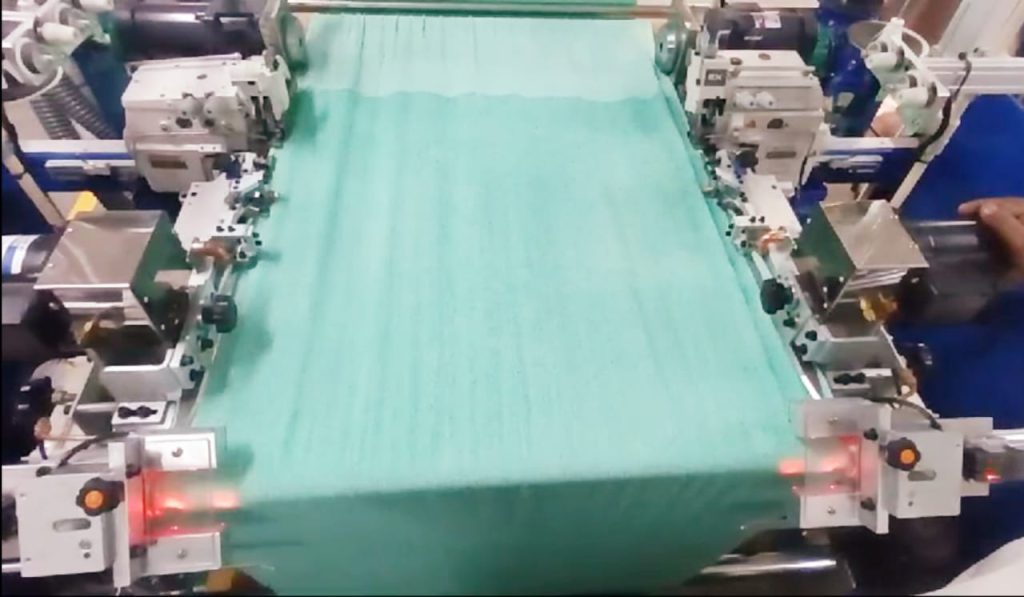

Bando Auto Length Hemming Machine

SKU: BANDO-HEMM-001

Bando is assembled with the best quality parts, including high-performance Japanese Pegasus sewing heads. Latest Control System, PLC, touch screen and Invertors.

Key Specifications

Speed

20 m/min

Working Width

Min 30cm - Max custom

Power

380V 3-Phase

Brand

Bando

Warranty

1 Year Parts & Labor

Related Products

Explore more solutions in this category

Bando Auto Cross Cutting Machine

State-of-the-art solution designed to deliver precision and efficiency in cross-cutting operations for…

Bando Auto Length Slitting Machine

Cutting-edge solution designed to meet the precision and efficiency demands of modern…